Product Description

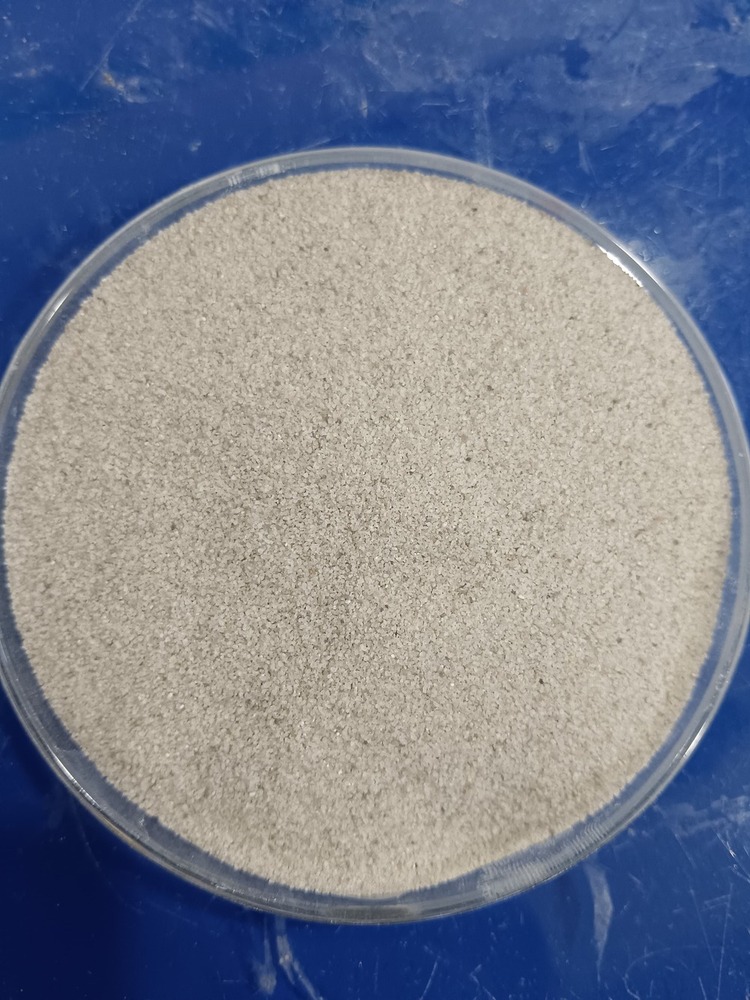

Premium Silica Sand Grits from Kutch Bentoclay High Purity Industrial Grade Sand

Kutch Bentoclay offers high-quality Silica Sand Grits, sourced from the mineral-rich regions near Kutch, Gujarat. Our silica sand grits are known for their uniform grain size, high purity, and excellent hardness, making them ideal for a wide range of industrial and construction uses.

Key Features of Kutch Bentoclay Silica Sand Grits

-

High Purity: Contains minimal impurities ensuring superior performance.

-

Consistent Grain Size: Uniform grit size for efficient filtration, abrasive blasting, and casting applications.

-

Excellent Hardness & Durability: Resistant to weathering and abrasion, suitable for heavy-duty use.

-

Chemical Stability: Inert and stable for use in diverse chemical processes.

-

Eco-Friendly: Naturally sourced and safe for environmental applications.

Applications

-

Glass manufacturing and foundry casting

-

Water filtration and purification systems

-

Abrasive blasting and sandblasting

-

Construction and concrete aggregate

-

Ceramic and refractory industries

Why Choose Kutch Bentoclay?

-

Sourced from trusted silica reserves in Kutch, India

-

Stringent quality control for consistency and reliability

-

Available in customized grain sizes and bulk packaging

-

Trusted supplier for industries nationwide and internationally

Consistent Quality for Industrial DemandsWe offer silica sand grits in a distinctive off-white, granular form tailored to meet industrial needs. Our commitment to maintaining a specific gravity of 2.2 ensures uniformity across applications, supporting processes like filtration, glass production, and foundry casting. Each batch undergoes careful handling for maximum utility.

Sourced and Exported from IndiaAs exporters, manufacturers, and suppliers based in India, we deliver silica sand grits to both domestic and international markets. Our strategic location allows us to ensure efficient transportation and timely dispatches, meeting the needs of diverse industries globally.

FAQs of Silica Sand Grits:

Q: How are silica sand grits used in industrial processes?

A: Silica sand grits are commonly used in industrial settings such as glass manufacturing, foundry casting, water filtration, and abrasive blasting, owing to their granular shape and consistent physical properties.

Q: What benefits do off-white silica sand grits offer for industrial applications?

A: The off-white color and granular form provide high purity and excellent performance in a variety of applications, ensuring minimal impurities and high efficiency for demanding industrial operations.

Q: When is it advisable to choose silica sand grits with specific gravity 2.2?

A: You should select silica sand grits with a specific gravity of 2.2 when your process requires stable, repeatable resultssuch as in the production of glass or as a filtration medium, where consistent density is crucial.

Q: Where do you source and export these silica sand grits from?

A: Our silica sand grits are sourced, processed, and exported from India, enabling us to efficiently supply markets both domestically and internationally.

Q: What is the general process for manufacturing silica sand grits?

A: The process involves mining high-quality silica sand, followed by grading, washing, and granulating to achieve the required size and shape before packaging for shipment.

Q: Can these silica sand grits be used across multiple industries?

A: Yes, their neutral chemical composition and granular form make them suitable for a wide range of industries, including glass, foundry, construction, water treatment, and abrasives.

Q: What advantage does sourcing from an Indian manufacturer provide?

A: Sourcing from an Indian manufacturer ensures access to abundant natural resources, cost-effective production, and reliable export logistics, offering competitive pricing and consistent supply.